What Is Supply Chain Management (SCM) and Why Is It Important?

quick answer

Supply chain management is the handling of the processes that transform raw materials into finished products, and Supply Chain Managers ensure these processes go smoothly so organizations can avoid massive recalls and potential lawsuits.

In This Article

In October 2022, the global supply chain market was valued at around $20 billion — making it one of the largest industries in the world.

However, for many people, the supply chain was hardly an afterthought — until COVID-19 caused massive setbacks to the supply chain and people were left wondering why their products weren’t showing up on time.

With the supply chain headlining the news on a daily basis, many people were left wondering: “what is the supply chain, exactly, and why is it important?”

Supply chain management is the handling of the processes that transform raw materials into finished products, and Supply Chain Managers ensure these processes go smoothly so organizations can avoid massive recalls and potential lawsuits.

As a result, regular economic flows rely on proper supply chain management, making it one of the most important and in-demand industries for employment.

In this post, we’ll explore how supply chain management works, why it’s significant for economic growth, and what you can do to become a Supply Chain Manager.

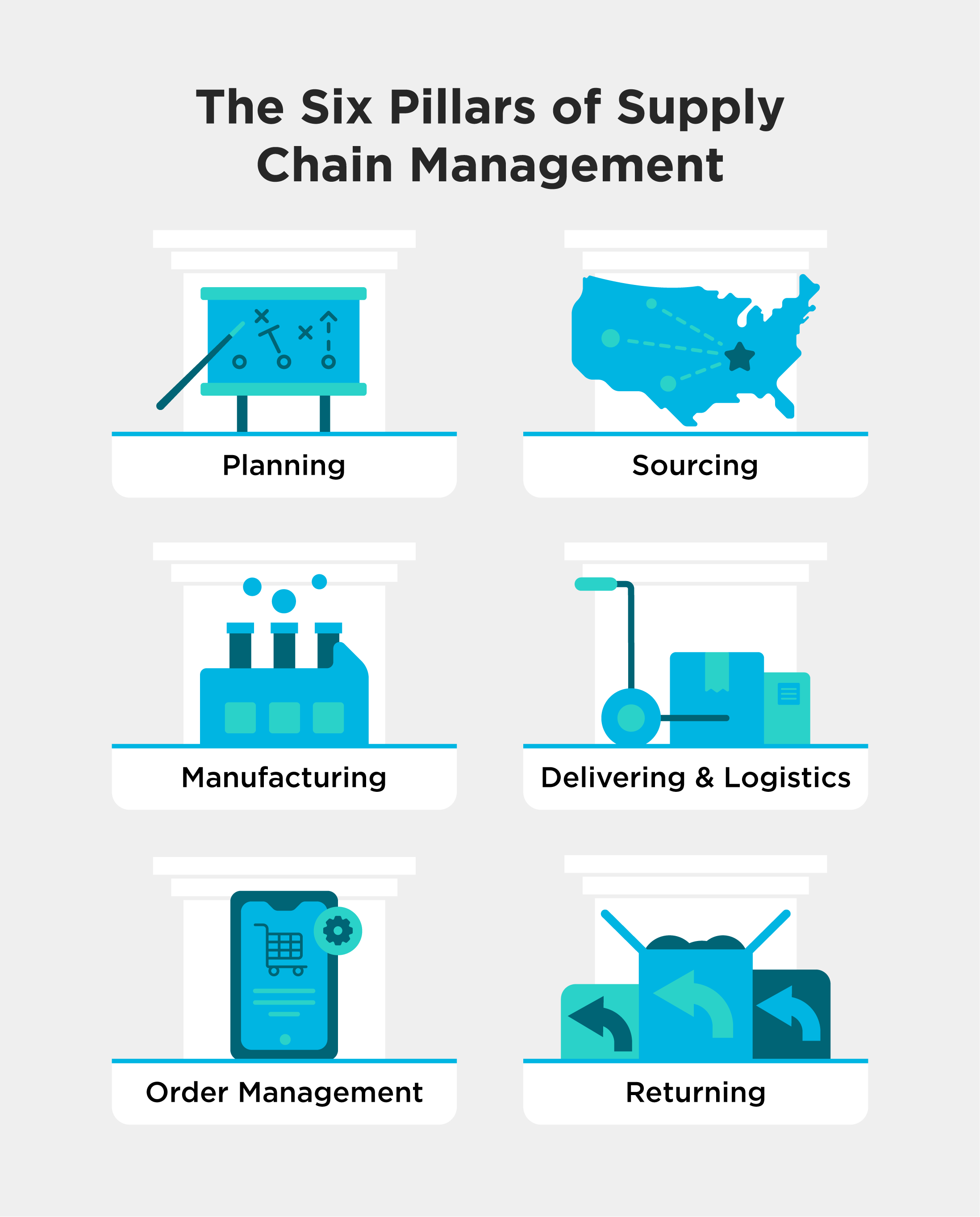

In an effort to reduce costs and keep processes as efficient as possible, SCM breaks down into six different parts. These include:

The planning phase occurs first and begins once the supply chain is established. In this phase, you’re essentially outlining the product journey from raw material to finished product. Firms have to decide what and how many materials they will need in each phase and the amount of labor required.

Proper planning is critical for avoiding setbacks later down the road. If you begin sourcing materials without knowing how many staffers you require, it can back up processes — leading to possible shutdowns at plants.

Now that you know what materials are required, it’s time to source those materials so you can begin manufacturing the product.

Sourcing requires working with a variety of different vendors to obtain the necessary materials. This phase is largely relationship-oriented, as you need to ensure you’re getting materials that align with the current market price and meet certain manufacturing specifications.

As a result, building trust with your vendors is essential to having success in this phase.

You have a plan and the materials to carry it out, and now it’s time to build. The manufacturing phase includes a number of different substeps. Some of these include:

The delivery stage is perhaps the most significant — as it is a way for a company to engage with individual customers who have purchased a product. Ensuring safe and efficient delivery is of utmost importance, as any hiccups will be associated with the company’s image.

However, it’s only natural that setbacks occur in this phase. Whether it’s inclement weather or another crisis, delays happen — so it’s important that you build crisis management into your SCM process. In most cases, this includes having numerous backup delivery options that can deploy regardless of the situation.

Order management gives customers real-time updates regarding the status of their orders, which can help establish trust between the company and the consumer.

Customers should have access to an online portal that tells them when their order is received, shipped, and delivered. Knowing the status of their order reassures consumers that their product wasn’t lost or forgotten.

It’s only natural that consumers will want to return some items after they receive them, so it’s important that Supply Chain Managers have a process in place to deal with returns.

Dealing with returns is another important element from an operations perspective. How a company deals with customer relations will be pivotal in whether or not a consumer buys from them again, so it’s critical to have an air-tight process in place.

We’ve touched on a few ways that organizations are directly involved in the supply chain, but SCM has implications that go beyond the success of individual companies. Additionally, proper SCM:

SCM plays a large role in the relationship between the customer and the firm — especially for B2C companies. When supply chain processes go awry, it reflects poorly on the firm. Therefore, to build better relationships with different firms, it’s important that Supply Chain Managers direct customer service perfectly.

SCM additionally reduces operating costs by decreasing purchasing costs, production costs, and overall supply chain costs.

Retailers rely on the supply chain to quickly deliver expensive items, thus limiting the time these items spend on the shelf. When expensive items spend a longer amount of time with the vendor, it leads to expensive inventory costs.

On the manufacturing side, the supply chain is pivotal in getting materials out for assembly in a timely manner. This works to avoid possible shutdowns at plants that can occur when processes get backed up.

Firms rely on SCM to save money on shipping expenses, large warehouses, and supply chain costs. If Supply Chain Managers are able to improve processes and save time and materials on shipping, it saves the firm money.

Additionally, if a firm is able to produce double the quantity of a good, they rely on the supply chain to keep up with its rising quantities. If the supply chain can successfully create more products and get them out the door, it means more profits for the firm.

Humans rely on the supply chain for basic survival necessities like food, water, and medicine. Therefore, lapses in the supply chain can have real human repercussions. Especially during natural disasters, adjustments have to be made to ensure people are getting the supplies they need to survive.

The supply chain is also responsible for keeping businesses open and workers employed. Take COVID-19, for example. Two out of three Canadian small businesses claimed to be impacted by supply chain disruptions due to the pandemic. For small businesses especially, the inability to receive products and raw materials often means having to close their doors — sometimes sooner rather than later.

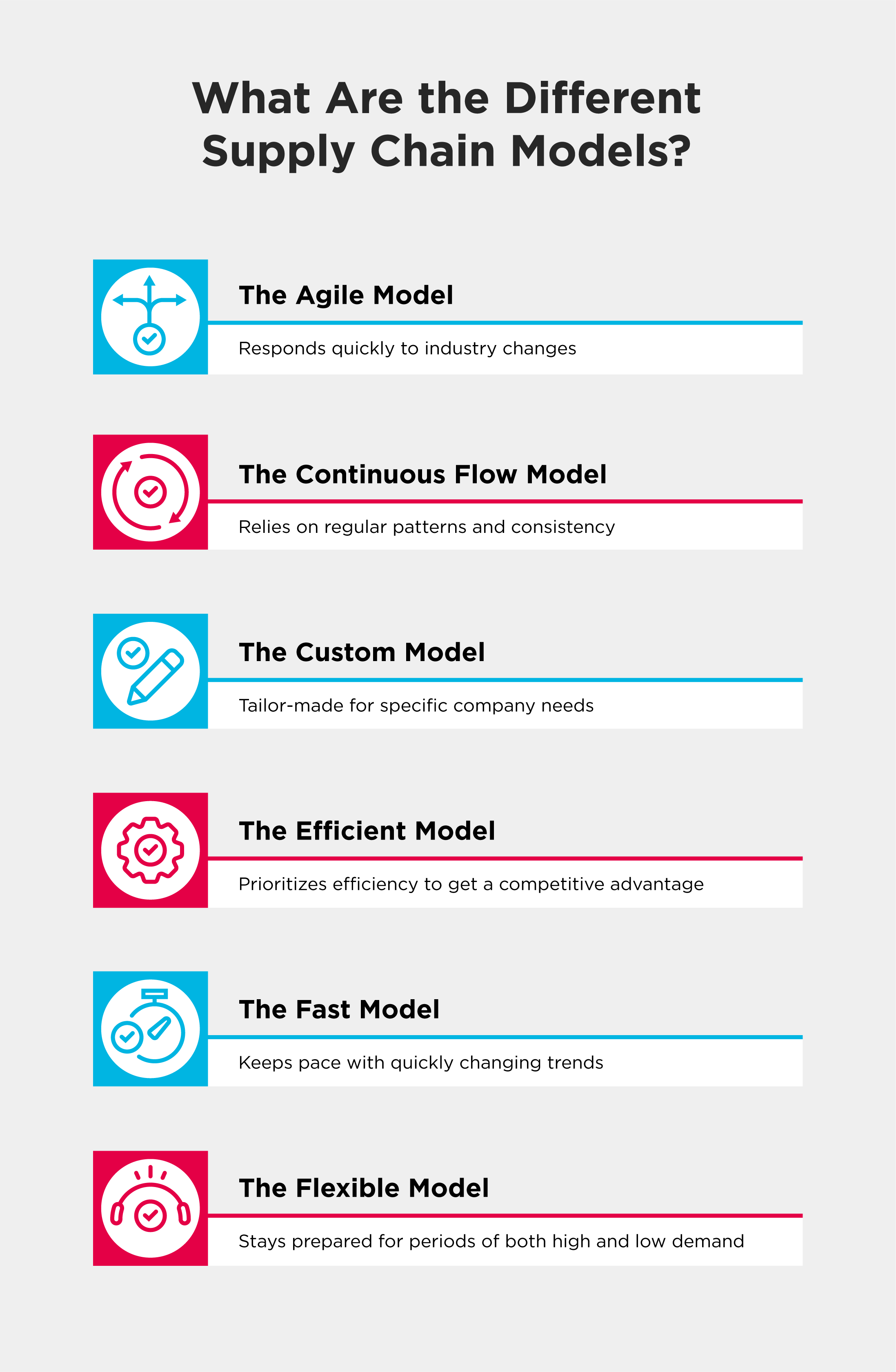

SCM isn’t the same for every industry, as different industries have specific needs that supply chain managers must account for. The six types of supply chain models include:

A more flexible supply chain model, the agile model responds quickly to rapid changes. Whether it’s customer demand or industry changes, the agile model is built to handle regular unpredictability. In this model, the final product isn’t created until it’s clear exactly how much demand there is.

Best for: Industries that are constantly changing to consumer demand. Think fashion, for example, where trends are constantly changing.

Unlike the agile model, the continuous flow model prioritizes consistency. In this model, manufacturers create the same product over and over again, operating under the idea that demand will not vary.

Best for: Industries with predictable and consistent demand patterns, like well-known food and beverage vendors.

If a company operates outside of the norm of its industry, the custom model may be best for them. The custom model requires specialized planning that suits the specific needs of the company.

Best for: Companies building new and unique products, typically with high-level technical needs. Automobile manufacturers generally use a custom model.

The efficient model prioritizes speed and efficiency, hoping to get a competitive advantage in their industry by getting products to consumers as quickly as possible. Companies that implement this model usually maximize machinery utilization to accomplish this.

Best for: Companies in competitive industries with tight profit margins. In industries where it’s difficult to differentiate products, the supply chain is used as a means to get ahead. Furniture wholesalers are a good example of companies that use the efficient model.

The fast model is used when a company needs to get a large batch of products made and delivered in a short period of time. Used most often for products with a short market lifecycle, the fast model ensures products get to consumers while they’re still popular.

Best for: Industries that rely on short-lived trends. Shoe companies use this model, since shoes go out of style relatively quickly.

Companies that experience both high and low periods of demand use the flexible model to be prepared for either. Companies impacted by seasonality generally use the flexible model to prepare themselves to meet higher demands during peak seasons.

Best for: Companies impacted by seasonality, like school supply providers, who rely on multiple vendors to get all the products they need.

If you’re wondering how to start a career in supply chain management, the path is relatively straightforward, though it does come with hard work, hands-on experience, and proper certification.

Follow the tips below to set yourself up for a role in the supply chain.

Becoming a Supply Chain Manager doesn’t require a Master’s Degree or PhD. Supply Chain Managers generally have attained training in:

While it doesn’t take multiple degrees to become a Supply Chain Manager, a diploma or Bachelor’s Degree is typically required to be considered for the role.

Our Online Business Certification at Robertson is a great first step in learning relevant supply chain skills — like Human Resources and Small Business Management. Some other relevant certifications include:

Beyond your degrees or diplomas, there are a number of other skills you can hone to make yourself the best possible candidate for a career in SCM.

The ability to think critically, creatively, and analytically is key in SCM, but there are also some hard skills you can learn that may set you apart in the job market. Microsoft Power Platform, an operation app, and Power BI, a data visualization software, are two great systems to learn if you aspire to be a Supply Chain Manager.

Taking data visualization courses as well as business analyst courses are other great ways to build tangible skills you can apply to a role in SCM.

When you obtain your degree and build up relevant skills, it’s time to fire off some applications. Structuring a picture-perfect resume is key to catching an employer’s eye and reaching the next step of the application process.

Some key components of a well-crafted resume include:

In the Supply Chain industry, you won’t start out as a manager. You’ll likely start in an analyst role and eventually work your way up to a manager role. However, the skills you pick up along the way will set you up for success in a managerial role.

A career path in Supply Chain Management may look like this:

If you’re aspiring for a career in SCM, there are a few courses you should consider to prepare you for a fulfilling career. The Logistics and Supply Chain Management Program at Robertson focuses on providing real-life skills that you can transfer to a career in SCM.

Some of the courses you’ll have the opportunity to take in this program include:

If you’re still wondering about what life is like in the supply chain, we’ve got you covered. Here are some common questions and answers about a career as a Supply Chain Manager.

The median salary of a Supply Chain Manager in Canada is $131,997.

Simply put, SCM is the handling of resources and processes as products go from raw materials to finished goods.

Consider a company that sells pants. SCM would include:

The main objective of SCM is to distribute goods to consumers when they need them. This means navigating difficult situations in order to ensure products still arrive at the right time.

You can launch into a career in SCM whenever you want, regardless of where you are in your current career. At Robertson, we can help put you on the fast track to becoming a supply chain manager.

Ready to get started? Apply to our Logistics & Supply Chain Management Program today!

In This Article

Once you take the first step, one of our Student Admissions Advisors will get in touch to better understand your goals for the future.

Apply Now